Finishing

In general, our productions are delivered to you with a final surface treatment. This can be done in two ways :

- No addition to the original material with processes such as tribofinishing, shot blasting, pickling or polishing. The purpose of this basic operation is to make the surface of the parts homogeneous in roughness.

- With addition to the surface to change the appearance, color, or technical characteristics of the parts (Electrical conduction, resistance to corrosion etc...)

| Treatment | Objective | Eligible metal | Comment |

| Polishing | Shiny appearance | Brass, Copper, Aluminium, Zamak | |

| Chroming | Display parts | Brass, Aluminium, Zamak | |

| Plating | Display parts | Brass, Aluminium, Zamak | |

| Tinning | Electrical Conduction | Brass, Copper, Aluminium | |

| Silvering | Electrical Conduction | Brass, Copper, Aluminium | |

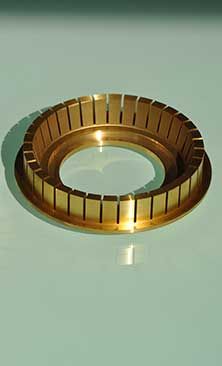

| Gilding | Protection, Luxe | Brass, zamak | After polishing |

| Copper plating | Electrical Conduction | Zamak | |

| Brassing | Display parts and for corrosion protection | Zamak | |

| Zink et bichromating | Protection against corrosion | Zamak | |

| Anodisation | Display parts and for corrosion protection | Hot forging aluminium only | The anodizing of aluminum alloy castings can be carried out on alloys whose % of Si is <4% |

| Epoxy paint | Display parts | Brass, Aluminium, Zamak | Risk of degassing on zamak parts |