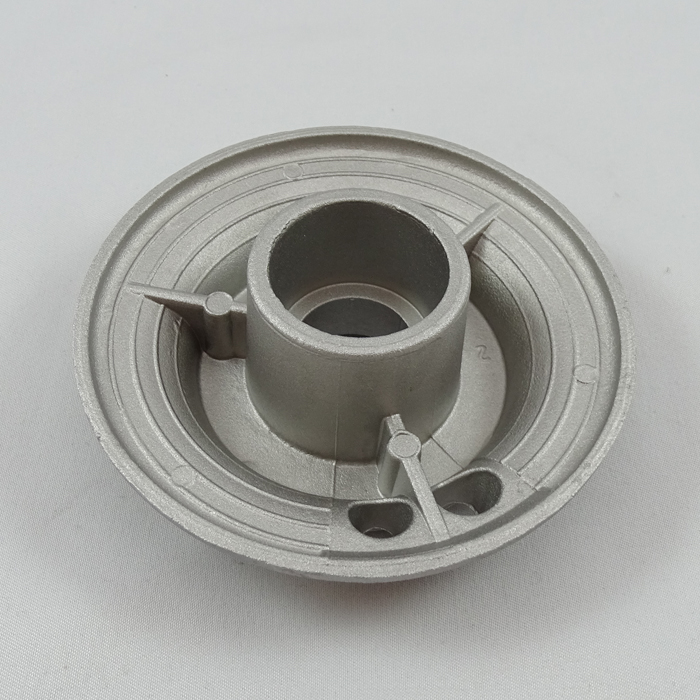

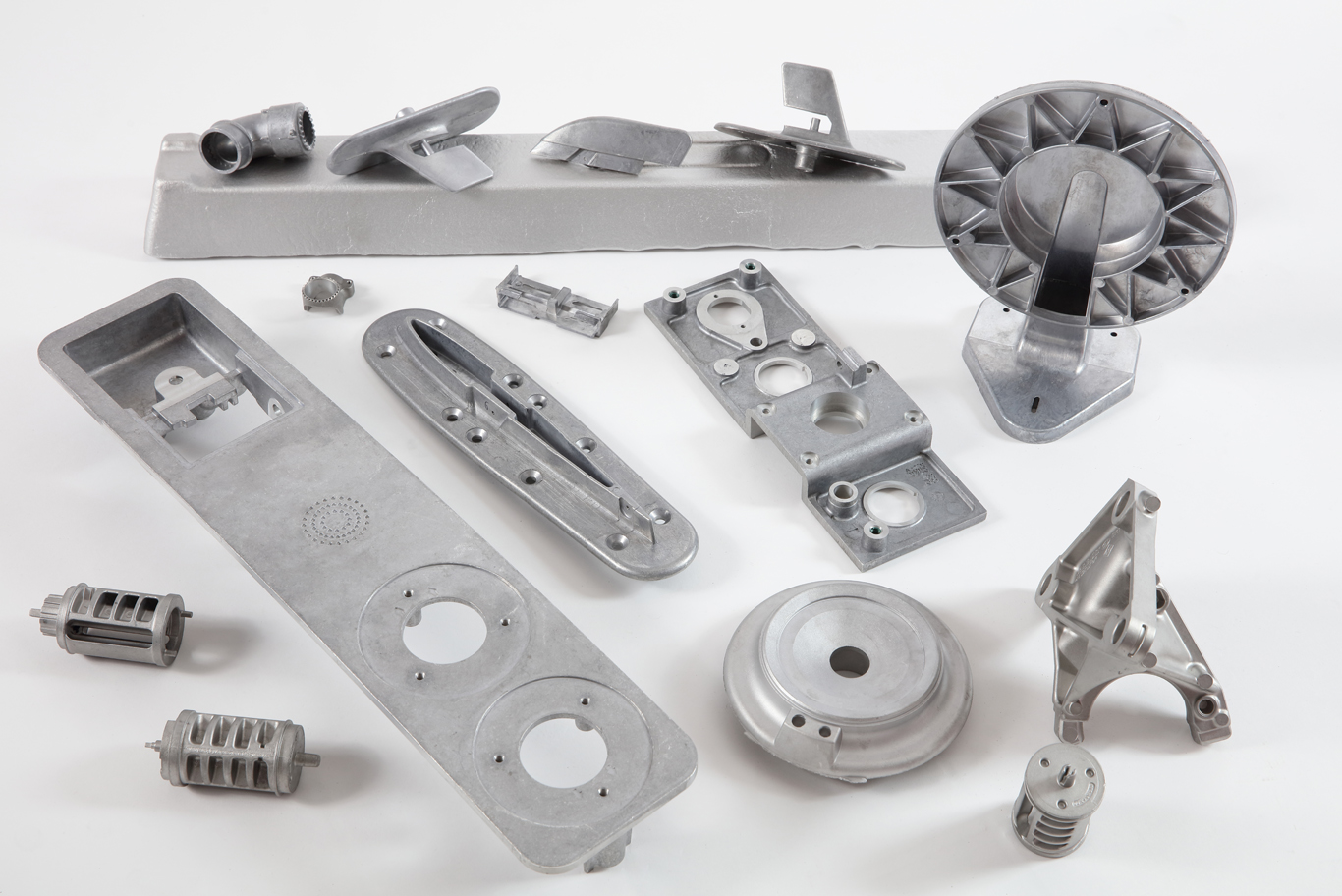

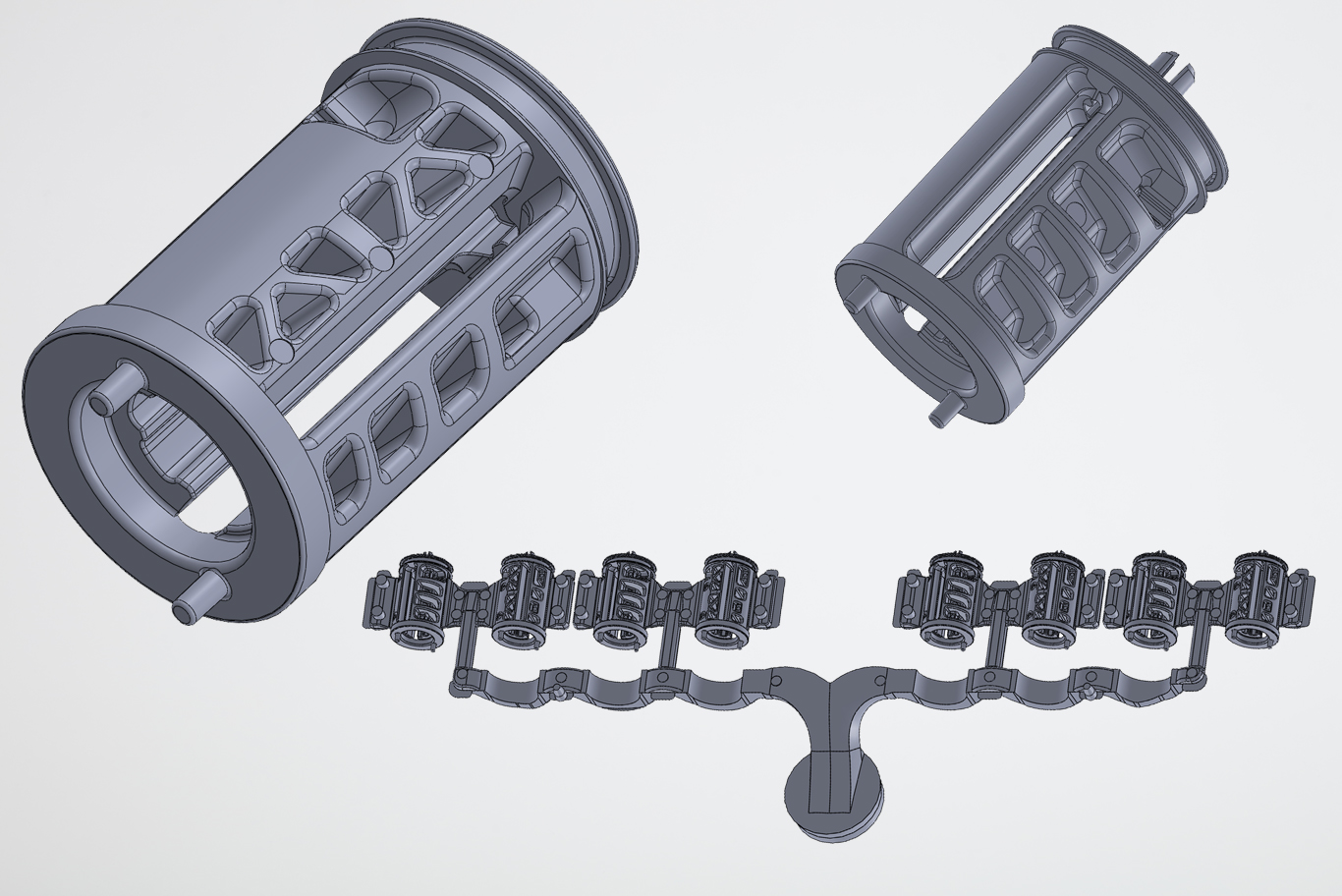

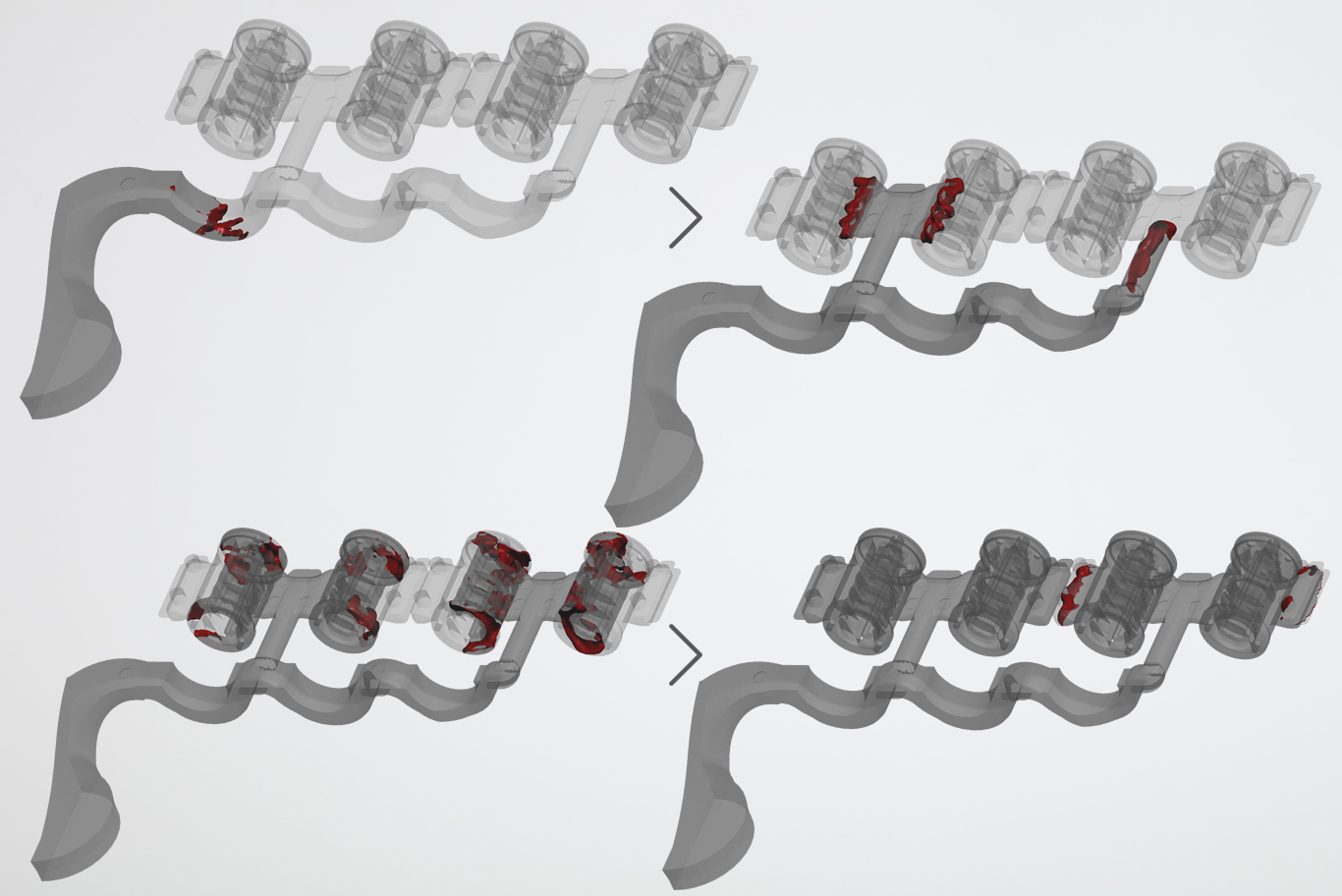

High pressure aluminium die casting

- High pressure die casting consist in injecting, under high pressure, a molten alloy in a metallic mold that solidifies quickly to form a workpiece.

- This transformation process allows to reproduce complex pieces with thin walls.

- It's a fabrication process economic and fast for the production in large production of light alloy parts.

- One of these main advantages is to have a high repeatability and a high tool life.

Characteristics of the aluminum used in high pressure die casting

- At equal volume, aluminum has 34% by weight of steel

- Aluminum is an excellent conductor of temperature, 1.8 times better than copper

- Die-cast aluminum has good rigidity and good strength / weight ratio

- It also offers the possibility of high working temperatures

- Recycling aluminum is easy and economical, environmentally friendly

| Designation according to european standard EN 1706 | Mechanical characteristics | Electrical conductivity MS/s | Thermal conductivity W(m K) | |||||

| Density | State | Rm N/mm² | Rp 0.2 N/mm2 | A% | HB | |||

| EN AC-43400 - AlSi10Mg(Fe) AS10G | 2.65 | F | 240 | 140 | 1 | 70 | 16 21 |

130 150 |

| EN AC-43500 - AlSi10MnMg | 2.64 | F T5 |

250 270 |

120 150 |

5 4 |

65 80 |

19 25 |

140 170 |

| 61 D1 (AS10G) | 2.55 | F | 300 | 180 | 5 10 |

85 | ||

| EN AC-44300 - AlSi12(Fe) AS12 | 2.65 | F | 240 | 130 | 1 | 60 | 16 22 |

130 160 |

| EN AC-46000 - AlSi9Cu3(Fe) AS9U3 | 2.75 | F | 240 | 140 | < 1 | 80 | 13 17 |

110 120 |

| EN AC-46200 - AlSi8Cu3 | 2.75 | F | 240 | 140 | 1 | 80 | 14 18 |

110 130 |

| EN AC-46500 - AlSi9Cu3(Fe)(Zn) | 2.75 | F | 240 | 140 | < 1 | 80 | 13 17 |

110 120 |

| EN AC-47100 - AlSi12Cu1(Fe) AS12U | 2.7 | F | 240 | 140 | 1 | 70 | 16 20 |

120 150 |

| ENAC-51500 - AlMg5Si2Mn EN 1706 | 2.65 | F | 250 | 140 | 5 | 70 | 15 21 |

110 130 |

| Designation according to european standard EN 1706 | Castability | Machinabilty | Weldability | Polishing | Chrome plating | Nickel plating | Tinning | Painting (20 to 30 microns) | Silvering Gilding |

Anodising | Corrosion resistance | Field of application |

| EN AC-43400 - AlSi10Mg(Fe) AS10G | A | B | C | B/C | B | B | C | B | B | E | C | Medium-sized parts, general mechanics |

| EN AC-43500 - AlSi10MnMg | A | B/C | B | D | B | B | C | B | B | E | B | Medium-sized parts, general mechanics |

| 61 D1 (AS10G) | D | B | B | C | B | B | E | Safety components, automobile, electrical goods | ||||

| EN AC-44300 - AlSi12(Fe) AS12 | A | C | D | D | B | B | C | B | B | E | C | Very complex parts, general mechanics |

| EN AC-46000 - AlSi9Cu3(Fe) AS9U3 | B | B | F | C | B | B | C | B | B | E | D | Parts produced in high quantitie, automobile, electrical goods |

| EN AC-46200 - AlSi8Cu3 | B | B | B | C | B | B | C | B | B | E | D | Parts produced in high quantitie, automobile, electrical goods |

| EN AC-46500 - AlSi9Cu3(Fe)(Zn) | B | B | F | C | B | B | C | B | B | E | D | Parts produced in high quantitie, automobile, electrical goods |

| EN AC-47100 - AlSi12Cu1(Fe) AS12U | A | C | F | C | B | B | C | B | B | E | C | Parts produced in high quantitie, automobile, general mechanics |

| ENAC-51500 - AlMg5Si2Mn EN 1706 | D | A | B | A | C | E | A | Pièces de sécurité automobile. Résistant à la corrosion. Soudure. Coulabilité difficile. |

Aptitude : A = Excellent, B = Good, C = Fair, D = Poor, E = Not recommended, F = Inappropriate

The anodizing of aluminum alloy castings can be carried out on alloys whose % of Si is < 4%. Aluminium alloys has a better resistance to corrosion if the Cu percentage is < 1% and the percentage of Zn is < 0.5%

M.C.T. Can not be in any way responsible for the exploitation of the indicative data of this commercial document