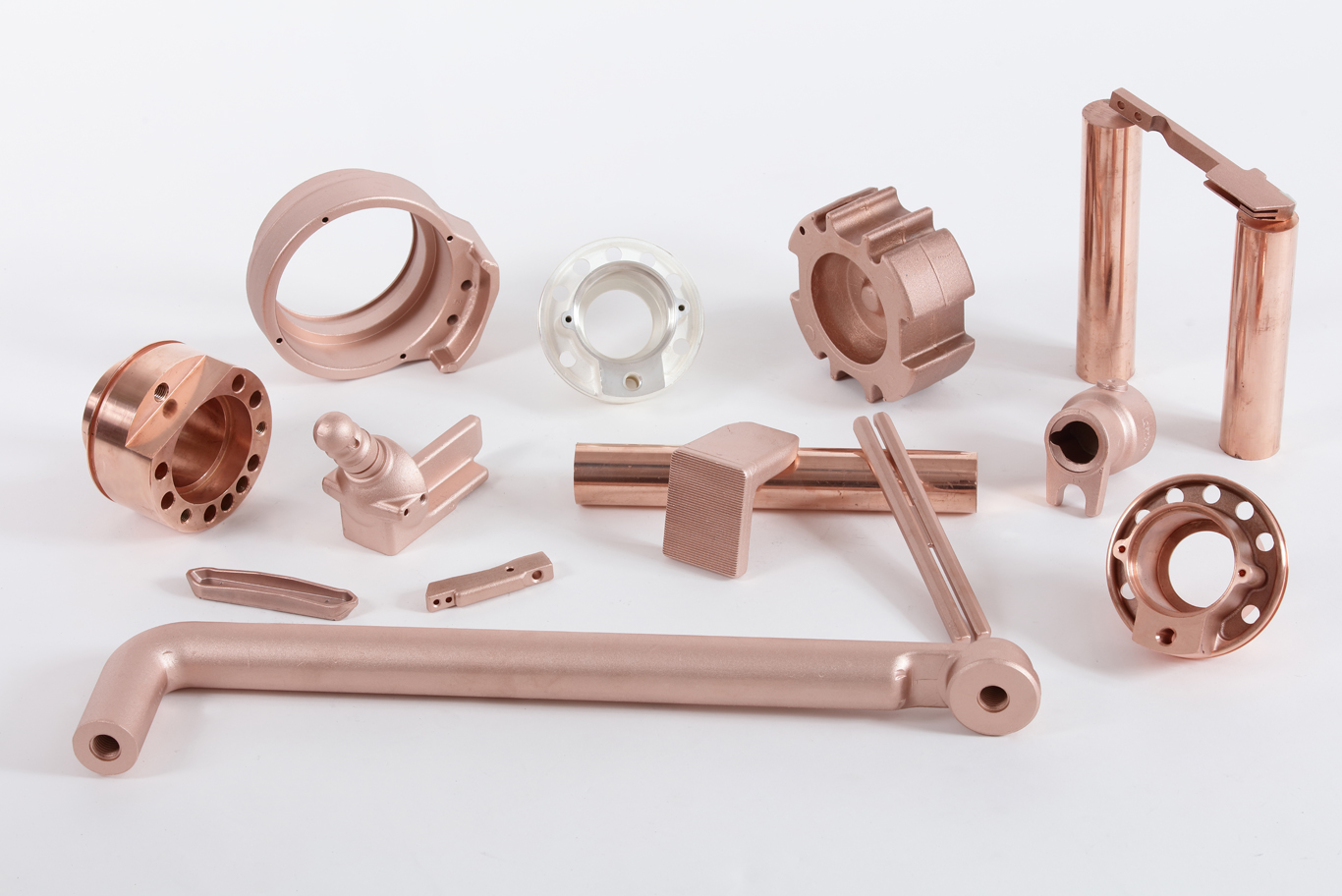

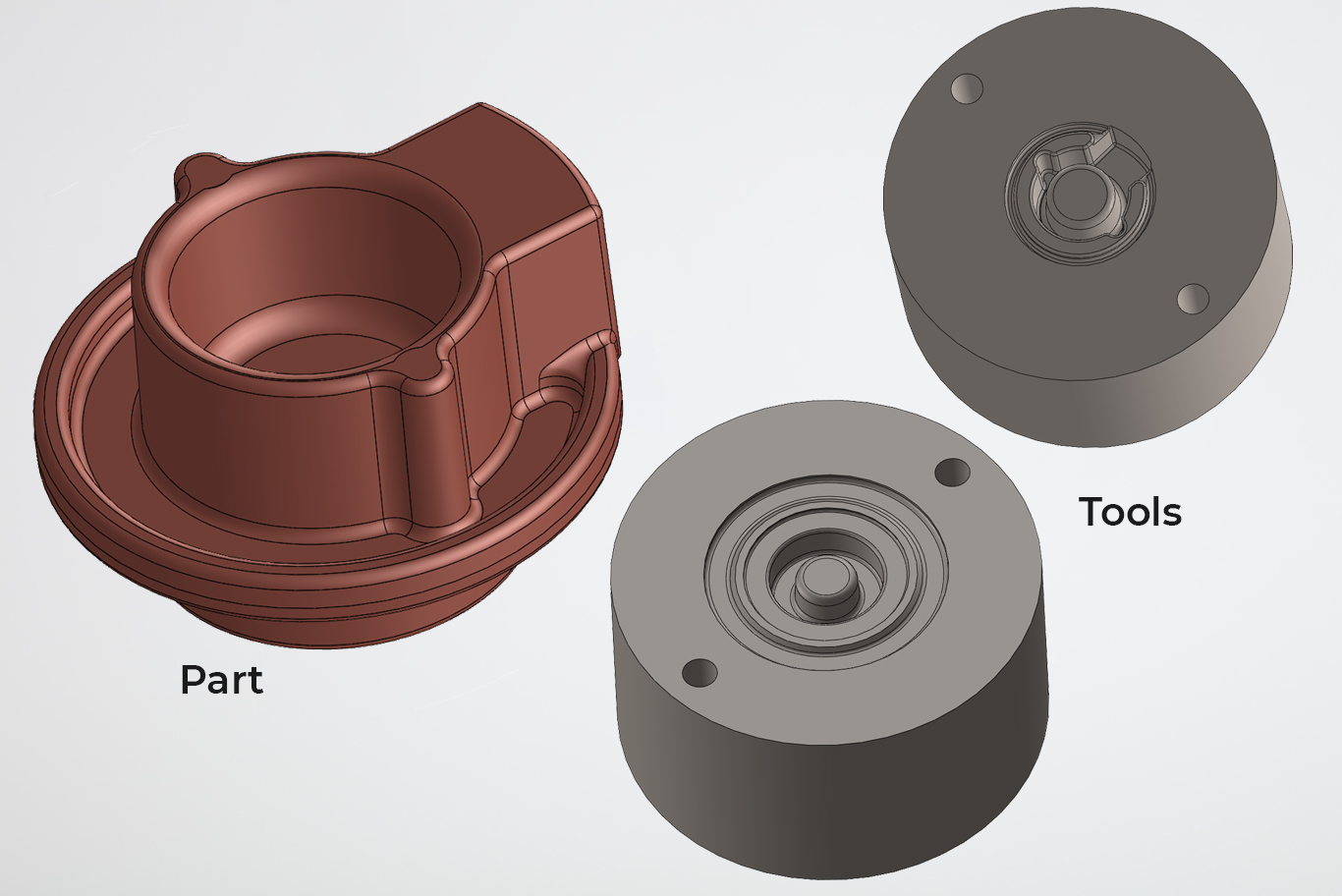

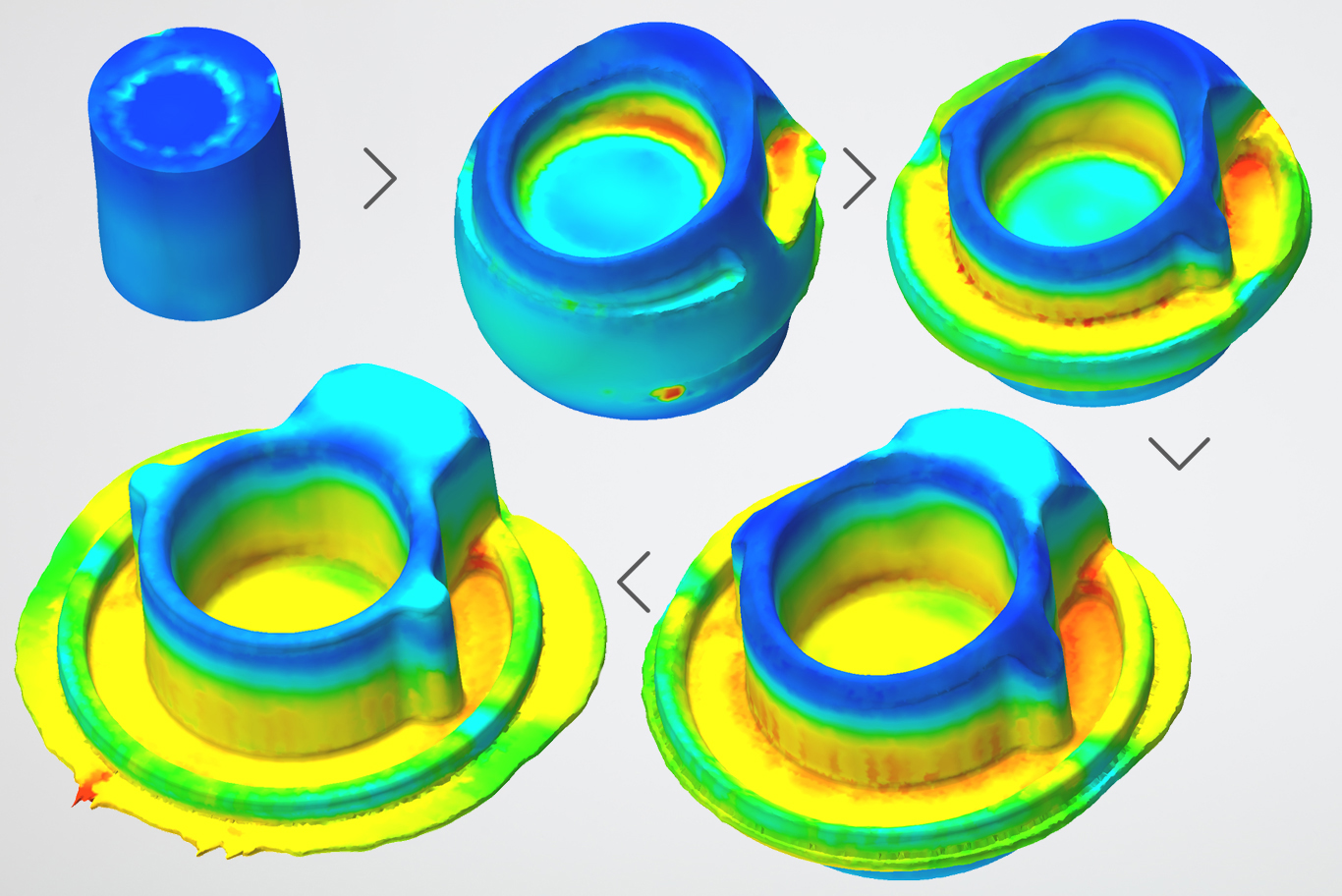

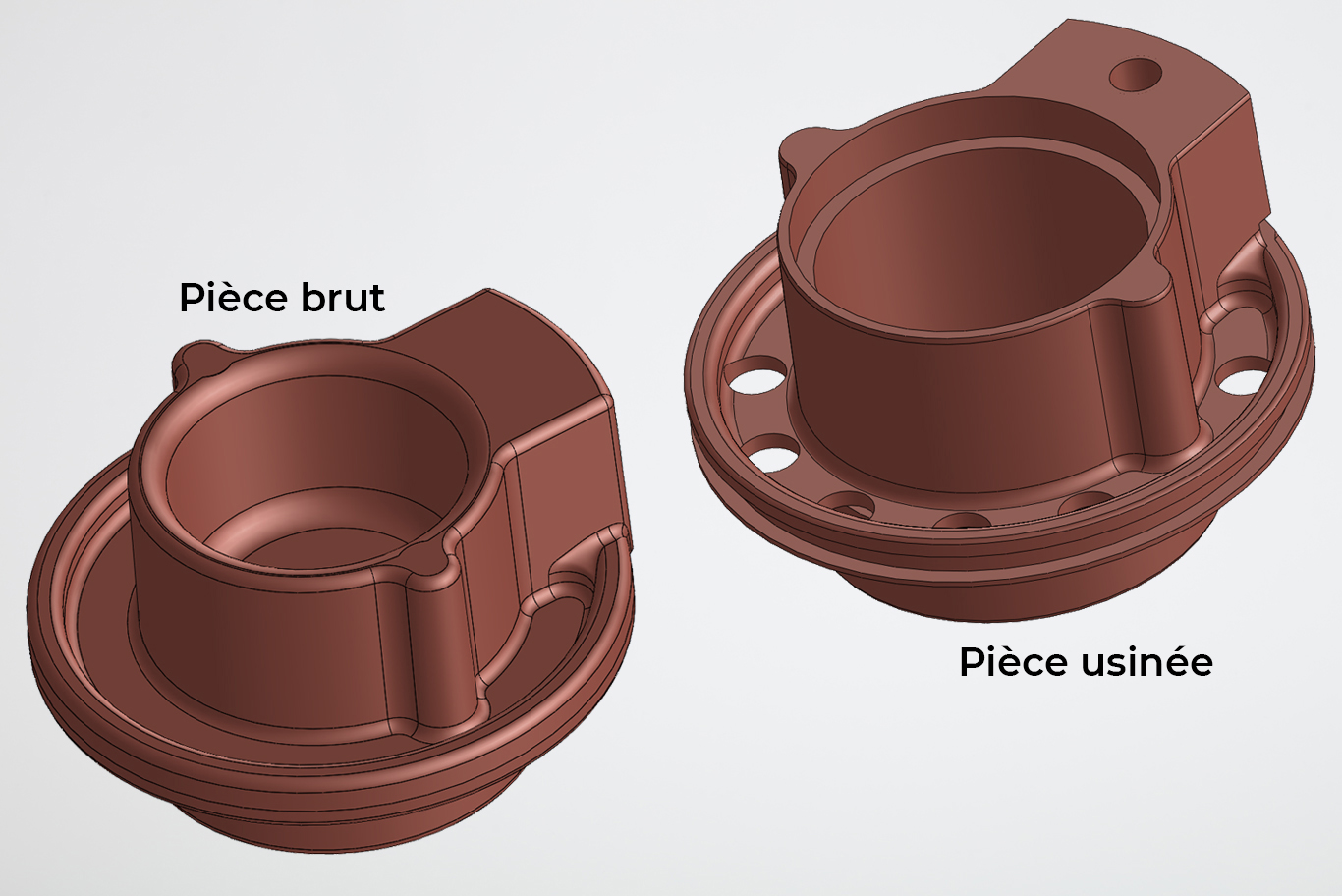

Copper hot forging

Characteristics of hot-forged copper

- Hot forging allows important deformations, refines the starting grain, create a favorable linear drawing

- Hot-forged brass offers the advantage of excellent material health, good surface condition, no porosity

- Numerous coating like silvering, tinning

- Copper offers an ideal conductivity for all the electrical applications

- It allows easy assemblies by stirring or crimping

- Recycling copper is easy and economical, environmentally friendly

- hot forged copper offers better mecanical characteristics than high pressure die casting

Different copper famillies

Cu-ETP

Pure electrolytic copper (99.9%)

Used for electrical applications

Cu-Te P

Copper comprising 0.4 to 0.7% of Tellurium

Good machinability, used for electrical applications

Cu-Cr-Zr

Copper comprising 0.5 to 1.2 % of chromium

The heat treatment considerably increases its mechanical characteristics

| Designation according to european standard EN 12165 | Density | State | Rm N/mm² | Rp 0.2 N/mm2 | A% | HB | Electrical conductivity %IACS | Thermal conductivity W/(m.K) |

| CW004A - CuETP Electro Copper | 8.9 | H040 | 200 | 50 | 30 | 40 | 100 | |

| CW106C - CuCr1Zr Chrome copper | 8.9 | H105 | 370 | 300 | 15 | 105 | 80 | |

| CW118C - CuTeP Tellurium copper | 8.9 | 250 | 200 | 5 | 90 | 94 | 369 |

| Designation according to european standard EN 12165 | Hot forging | Machinabilty | Weldability | Polishing | Chrome plating | Nickel plating | Tinning | Painting | Silvering gilding | Anodisation | Corrosion resistance | Field of application |

| CW004A - CuETP Electro copper | A | C | B | A | A | A | A | A | F | B | electrical equipment | |

| CW106C - CuCr1Zr Cuivre au chrome | B | B | B | F | ? | ? | F | B | electrical equipment | |||

| CW118C - CuTeP Telluriem copper | C | A | B | F | E | E | F | B | Electrical equipment, buses laser plasma (?), electric heating |

A = Excellent | B = Good | C = Fair | D = Poor | E = Not recommended | F = Inapropriate

|

Metallurgical states on copper bars and copper alloys |

Metallurgical states on hot forged pieces |

||

|

Crazed states |

Hardness level |

State |

Hardness HB |

|

O |

Annealing |

H070 |

70 |

|

H11 |

1/4 hard |

H100 |

100 |

|

H12 |

1/2 hard |

|

|

|

H13 |

3/4 hard |

|

|

|

H14 |

4/4 hard |

|

|

M.C.T. Can not be in any way responsible for the exploitation of the indicative data of this commercial document