Sustainable production

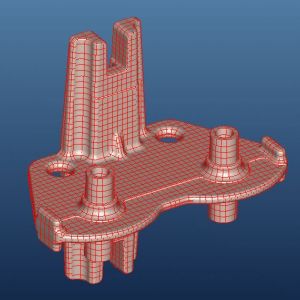

The foundry :

- Six Zamak injection press of 200, 130, 90, 63, 20, 15 and 10 tons

- Six Aluminium injection press of 660, 650, 530, 530, 400 and 220 tons

- Two Zamak micro injection modling presses

- Coquilleuses 4 axes (?)

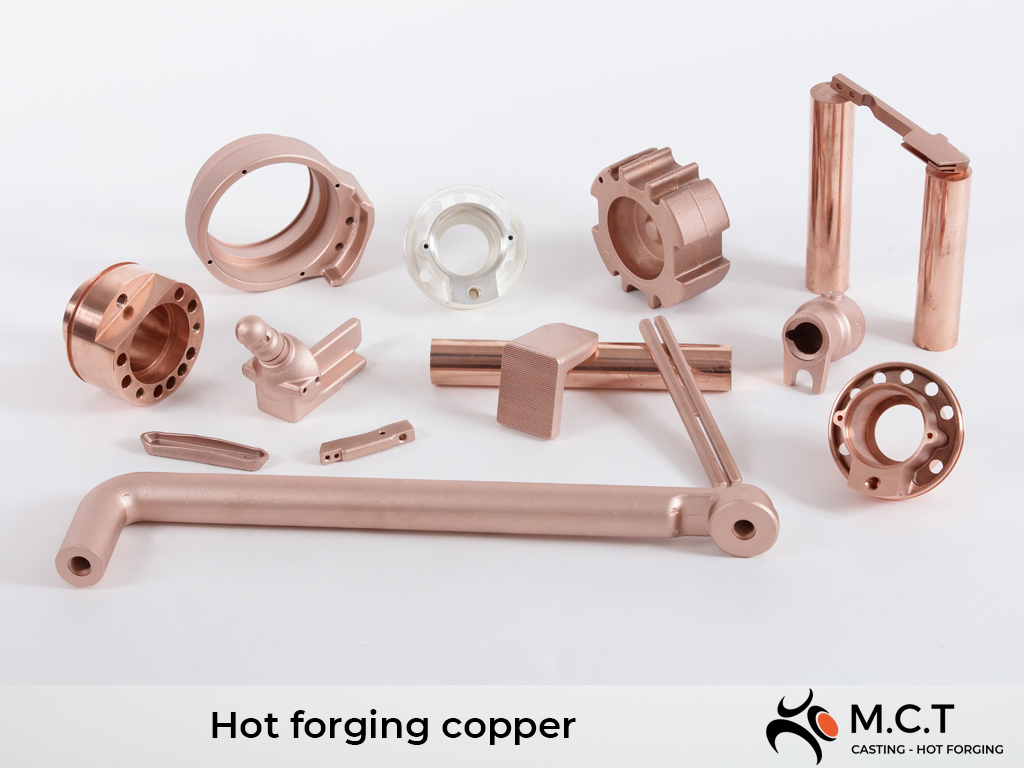

Hot forging :

- Two press of 400 and 220 tons

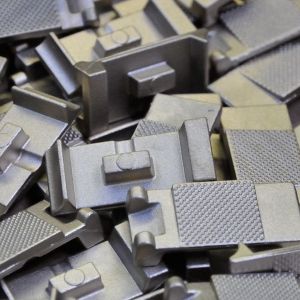

The cutout :

- Six hydraulic presses of 40, 30, 30, 20, 20 and 15 tons

- Five straightside presses of 50, 40, 30, 25 and 10 tons

- Two fusing presses of 30 tons

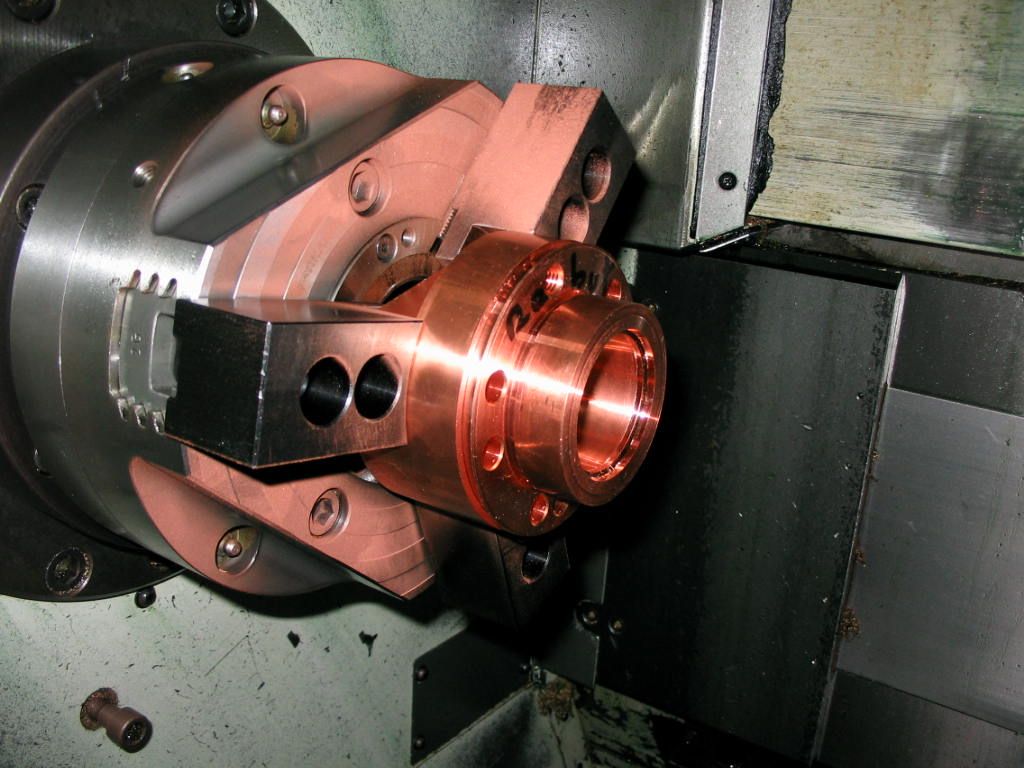

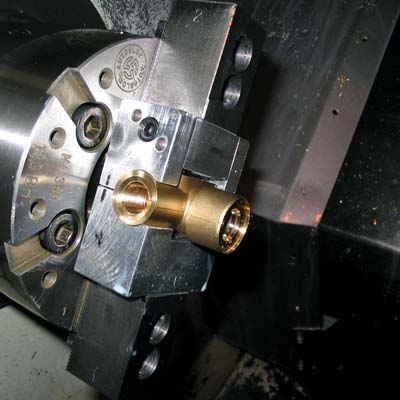

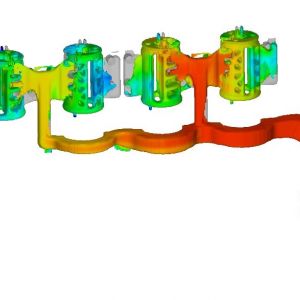

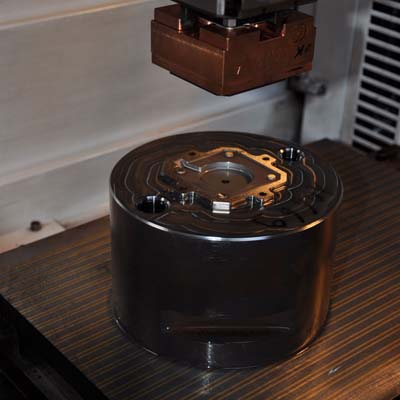

The machining :

- Deux centres d’usinage quatre axes avec palettisation (?)

- Four conventional transfer machines 9, 6 and 3 head

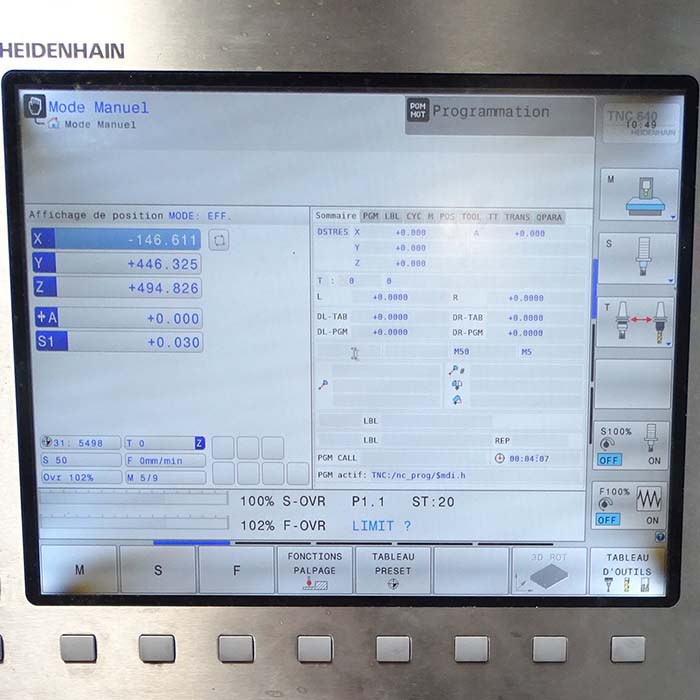

- Computer controlled transfer machines 15 heads and 64 axes totaly digitised

- Dix machines diverses de reprise, perçage, taraudage, tournage etc... (?)

The finishing part :

- Trois spiratrons (?)

- Two grease removing machines

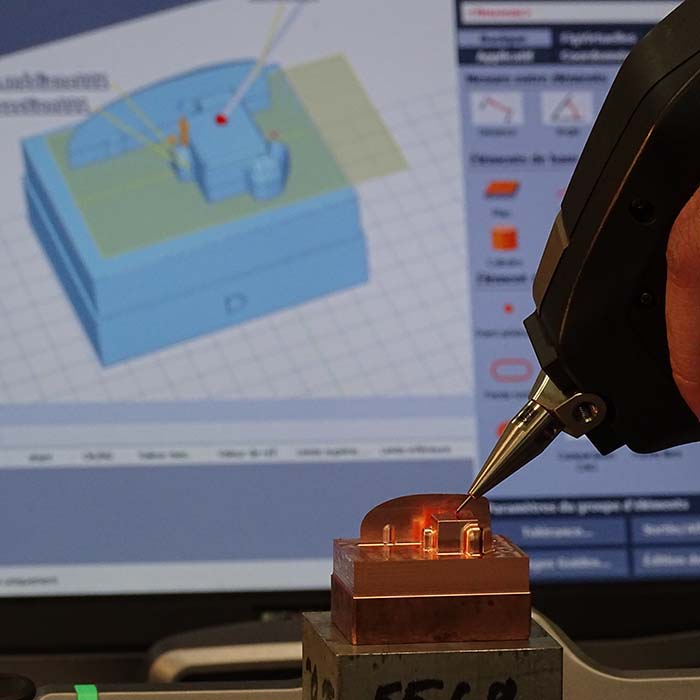

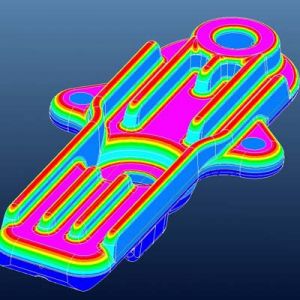

The control deprtment :

- Deux machines de contrôle 3D motorisées et surfaciques par comparaison de surfaces avec des fichiers CAO. (?)

- Testing machine

- Statistic control SPC

- Surface testing

- Hardness control

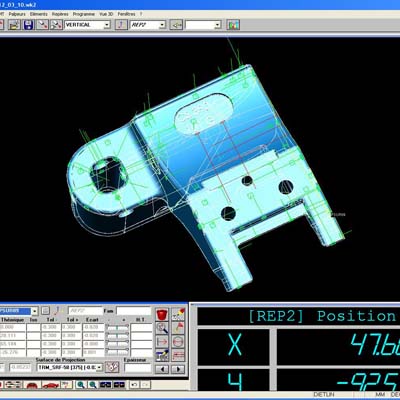

The study office :

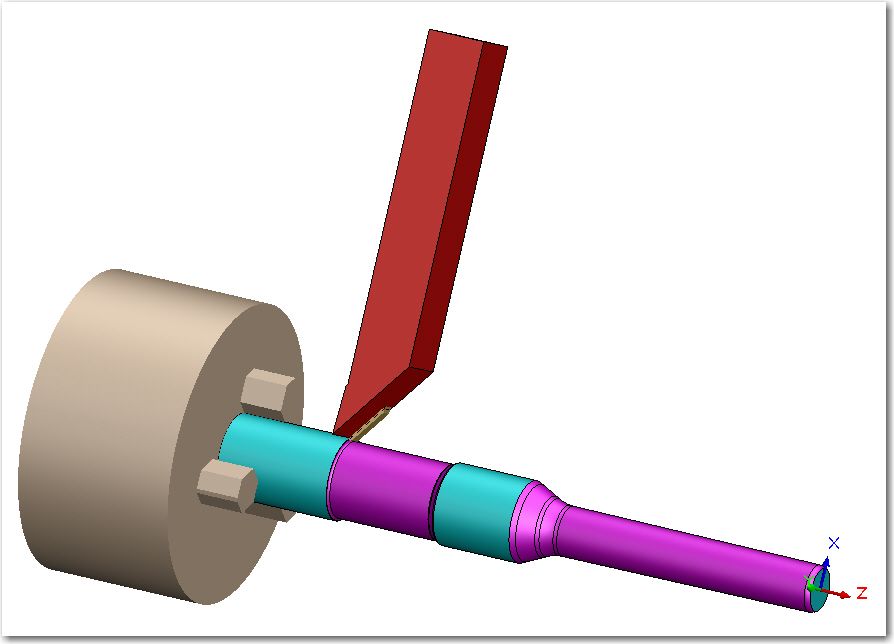

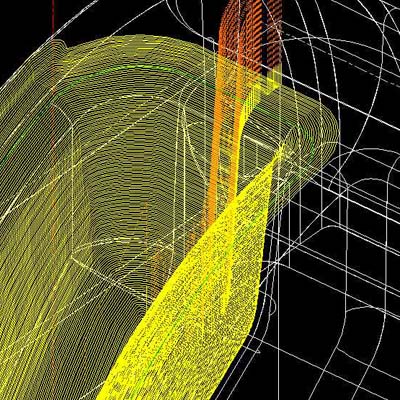

- A work station with a FAO 3D system for grinding and le tournage (?)

La mécanique pour les outillages :

- CNC mill

- Deux tours conventionnels (?)

- Two conventional mill

- Rectifieuses et pantographe (?)