Parts from A to Z

With over 70 years of experience, MCT offers global solutions tailored to its customers' needs.

Thanks to our sales department, we offer you a personalized approach for each of your projects.

Accompanying and monitoring includes the following steps:

1- Study and feasibility

2- Co-design of parts

3- Prototyping Phase

4- Creation of tools

5- Presentation of initial samples

6- Implementation of a packaging and a supply chain

7- Finishing

8- Assembly

9- Production monitoring

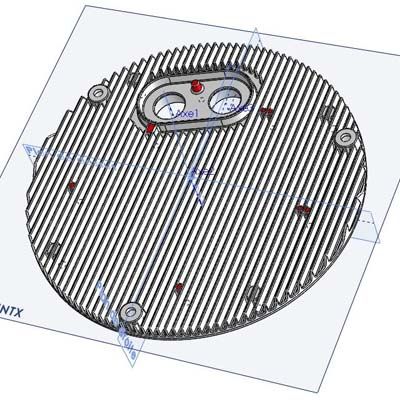

1- Feasibility study

We offer you our multi-job expertise for the studies of your parts and the feasibility of your projects.

Our design department shares the feedback gained during the previous designs of parts.

Moreover, our multi-business approach: High pressure die casting, gravity foundry, hot forging and machining, allows us to offer you the best solution, without prejudice, adapted to your needs for the association of technology and matter.

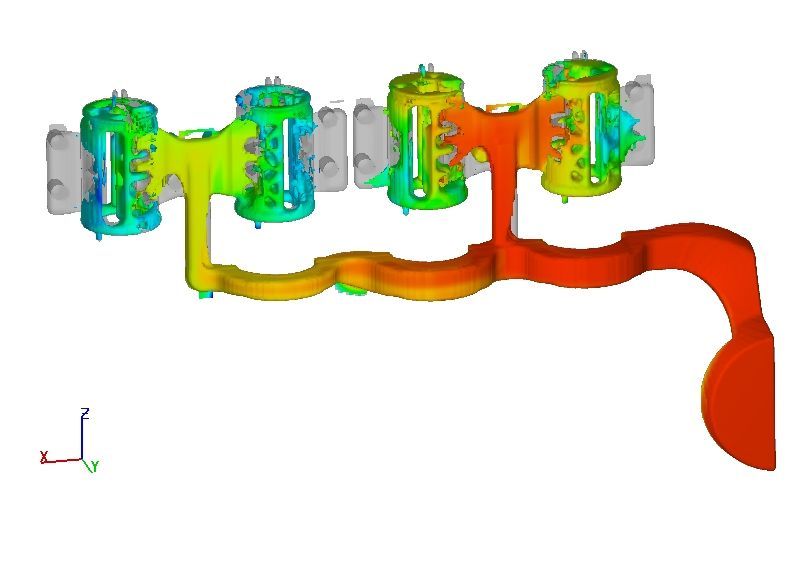

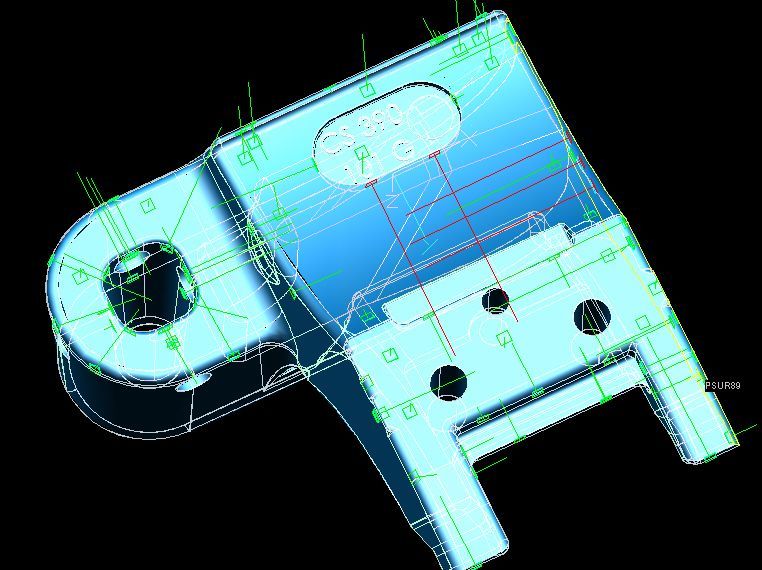

2- Co-design of parts

We propose to co-design the parts from the beginning of the project with our customers taking into account its needs and adding our "layer" business related to the choice of the technology and the chosen material.

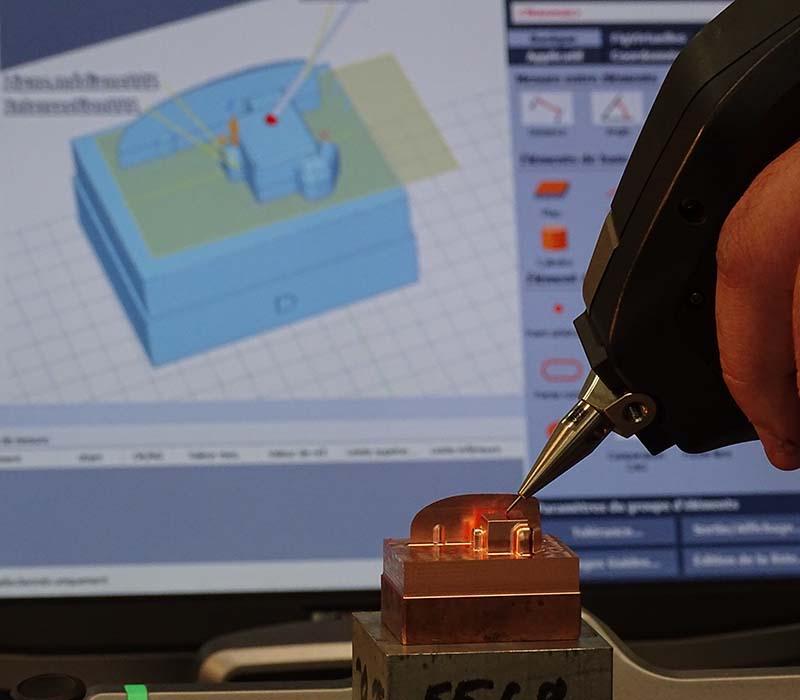

3- Prototyping Phase

When the design of the part is finished, we can propose you to make a prototype in order to validate the good assembly, the bulk, the appearance etc..

The prototypes can be realized in digital machining, respecting the final material or in 3D printing.

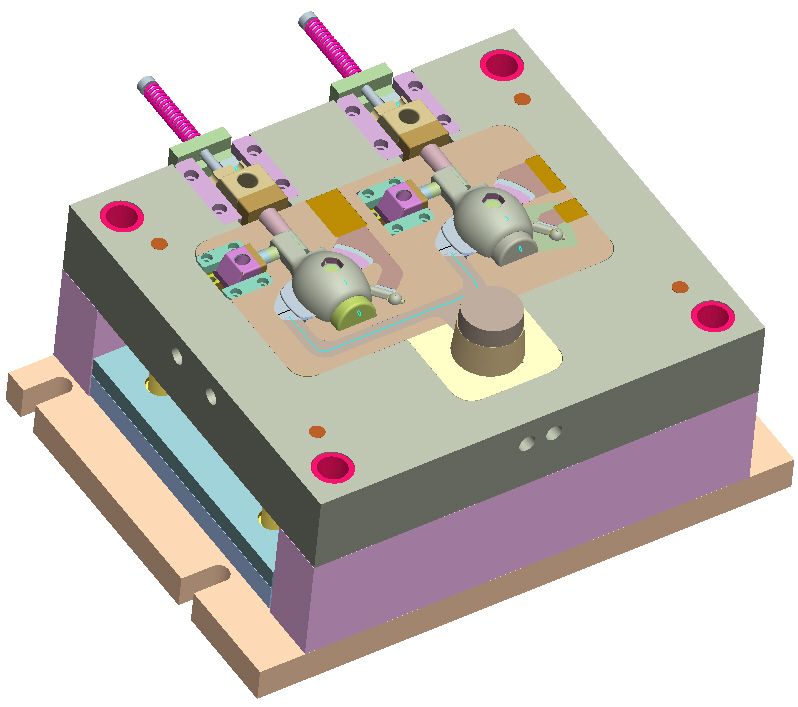

4- Creation of tools

We are equipped with a workshop of mechanics which realizes and develops the maintenance of your tools.

When a new tool is created, a production schedule is communicated to the customer.

5- Presentation of initial samples

Once the tooling has been developed, we start producing the initial samples.

Our quality department carries out a metrological survey of the coasts and records the information in a document which is sent to you.

We submit the initial samples and the metrology.

6- Implementation of a packaging and a supply chain

We are able to offer you standard packaging type GALIA / ODETTE with traceability of the productions or tailor made packaging of the type: Individual bag, Carton with compartment, Plastic honeycomb etc.

In addition, we can create a specific labeling according to your needs.

Finally, to ensure a logistics flow adapted to your demand, we can set up a shuttle system for the return of packaging, KANBAN or any other management.

7- Finishing

We can take care of the different surface treatments like: silvering, gilding, polishing, tinning, chromium plating, zinc plating, copper plating, brass plating, bichromating, anodization, epoxy paint, liquid paint… Always with the aim of providing you with a comprehensive solution.

We take care of the complete subcontracting and we carry out the selection of partners by regular audits.

8- Assembly

Our strategy to offer you global projects also takes into account the assembly of components in order to provide you with sets or sub-assemblies.

Our experience of machines allows us to be a force of proposition.

9- Production monitoring

We assure a tracking of your orders as close to your needs as possible.

The provision of an order estimate allows us to better anticipate your orders and thus offer you an optimized service rate.