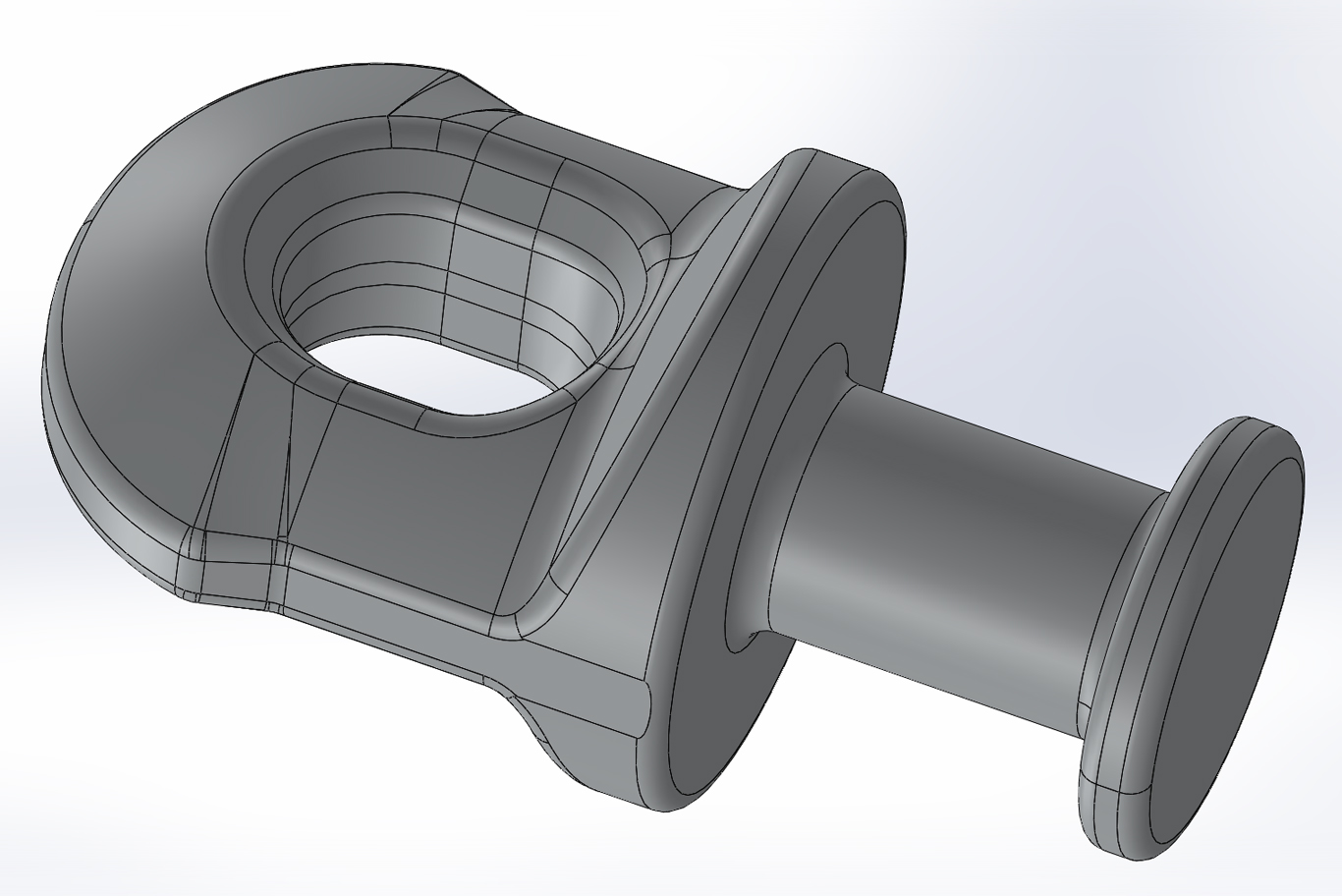

Hot forging Aluminium

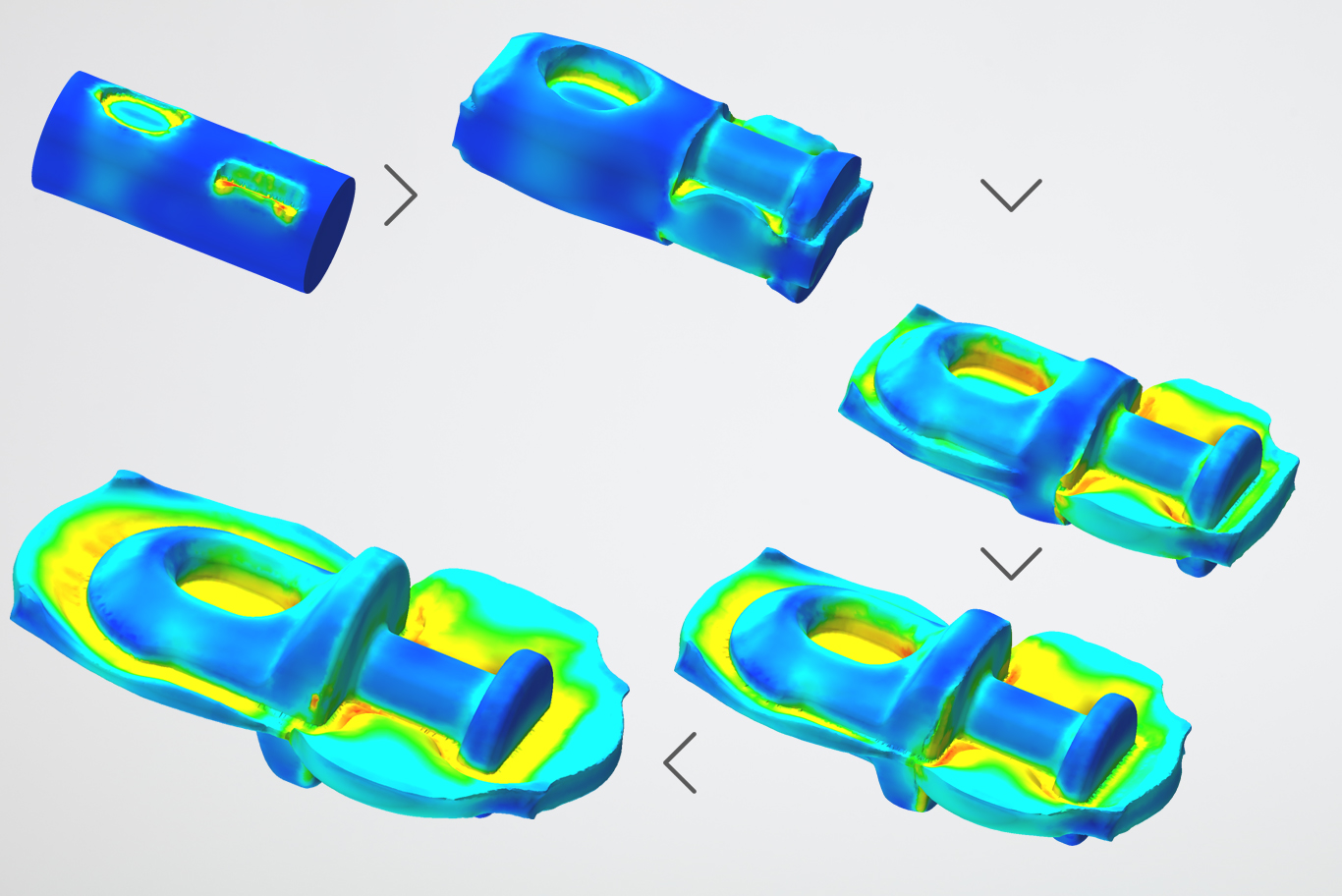

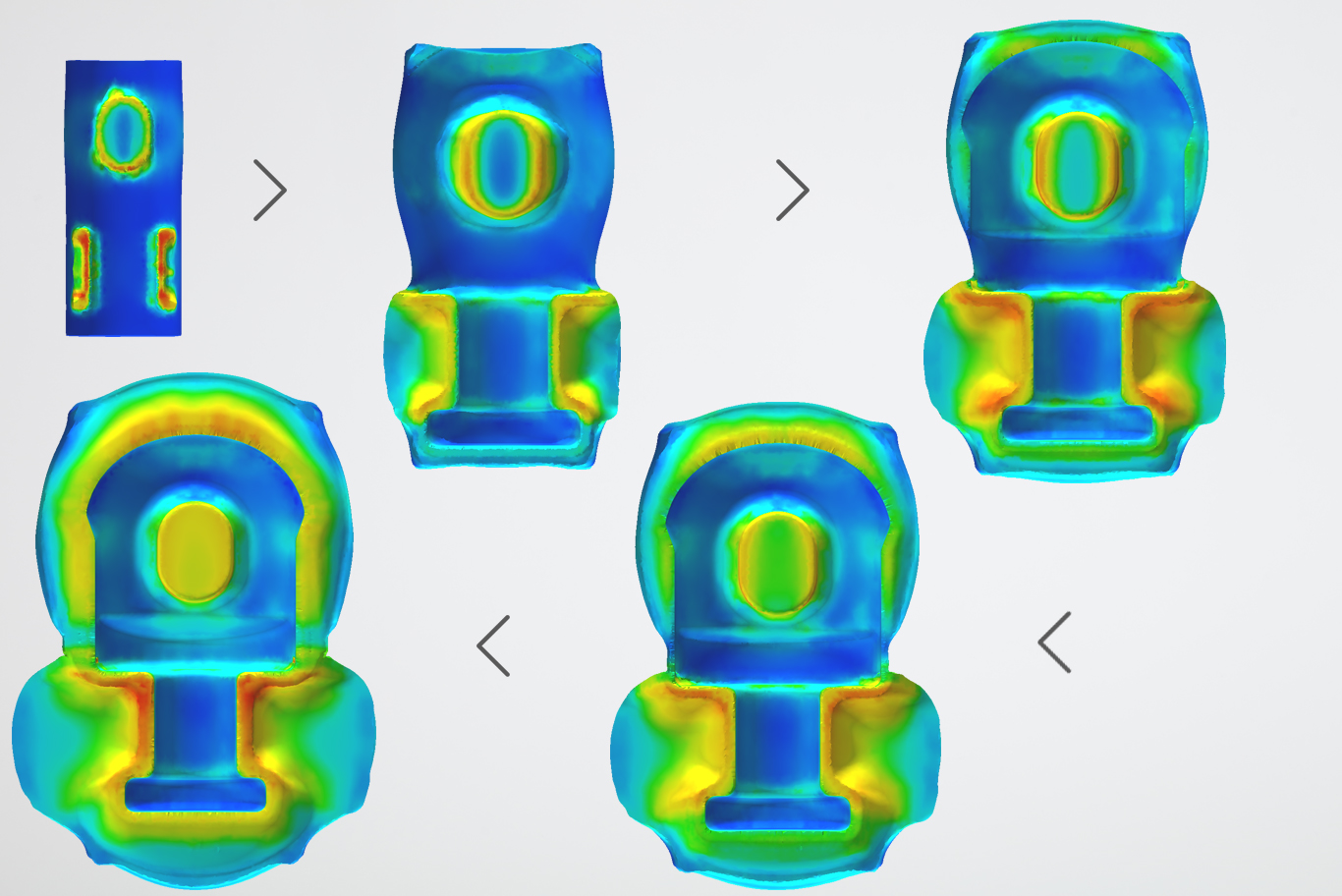

![]() Watch a simulation video of hot forging aluminium

Watch a simulation video of hot forging aluminium

Characteristics of hot-forged aluminum

- Hot-forged aluminium offers better mechanical characteristics than die casting

- Hot-forging crée un fibrage linéaire favorable (?)

- Hot-forged Offers the advantage of excellent material health, good surface condition, no porosity, very good waterproofing

- At equal volume, aluminum has 34% of the weight of the steel (density 2.7 for 7.85)

- Aluminum is an excellent conductor of temperature, 1.8 times better than copper

- Recycling aluminum is easy and economical, environmentally friendly

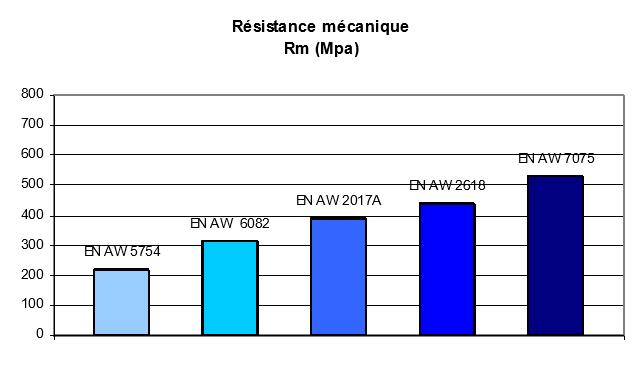

The different aluminum families

1000 Used for mechanical components with anodization (electricity, chemistry, agri-food)

2000 Used in industry including aeronautics (easy machining)

5000 Used in construction

6000 Used in the automotive and nautical industries (resistance to corrosion)

7000 Used in armaments, aeronautics and sport (mechanical resistance)

| Designation according to european standard EN 573-3 | Mechanical characteristics | Electrical conductivity MS/s | Thermal conductivity W(m K) | |||||

| Density | State | Rm N/mm² | Rp 0.2 N/mm2 | A% | HB | |||

| EN AW-1050A (AI99.5) | 2.70 |

0 H18 |

60 145 |

125 |

25 3 |

20 42 |

62 | 231 |

|

EN AW-2017A - AICu4MgSi AU4G |

2.79 | T4 | 390 | 235 | 12 | 105 | 34 | 134 |

|

EN AW-2024 - AICu4Mg1 AU4G1 |

2.77 | T4 | 440 | 300 | 11 | 110 | 30 | 120 |

| EN AW-2618A - AICu2Mg1.5Ni | 2.76 | 0 | 440 | 390 | 8.5 | 135 | 16 22 |

130 160 |

|

EN AW-5754 - AIMg3 AG3 |

2.67 | 0 | 220 | 100 | 23 | 50 | 33 | 132 |

|

EN AW-6060 - AIMgSi ASG |

2.70 | T6 | 305 | 270 | 13 | 95 | 52 | 200 |

|

EN AW-6082 - AISiMgMn ASG |

2.70 | T6 | 305 | 270 | 13 | 95 | 52 | 200 |

|

EN AW-7075 - AIZn5.5MgCu AZ5GU |

2.80 | T6 | 530 | 450 | 8 | 150 | 33 | 130 |

| Designation according to european standard EN 573-3 | Castability | Machinabilty | Weldability | Polishing | Chrome plating | Nickel plating | Tinning | Painting (20 to 30 microns) | Silvering Gilding |

Anodising | Corrosion resistance | Field of application |

| EN AW-1050A (AI99.5) | A | C | A | A | B | B | A | A | B | A | A |

Used for mechanical components with anodization (electricity, chemistry, agri-food) |

|

EN AW-2017A - AICu4MgSi AU4G |

B | A | D | B | B | B | A | A | B | B | C |

Used in aviation industry |

|

EN AW-2024 - AICu4Mg1 AU4G1 |

B | A | D | B | B | B | A | A | B | B | C | Used in aviation industry |

| EN AW-2618A - AICu2Mg1.5Ni | B | A | D | B | B | B | A | A | B | B | C |

Used in aviation industry |

|

EN AW-5754 - AIMg3 AG3 |

B | C | A | B | B | A | A | B | A |

Used in construction |

||

|

EN AW-6060 - AIMgSi ASG |

A | C | A | A | A | A | A | A | B | A | A |

Used in Utilisé dans The automotive and nautical industry (corrosion resistance) |

|

EN AW-6082 - AISiMgMn ASG |

A | C | A | A | A | A | A | A | B | A | A |

Used in Utilisé dans The automotive and nautical industry (corrosion resistance) |

|

EN AW-7075 - AIZn5.5MgCu AZ5GU |

B | A | B | B | B | B | A | A | B | B | C |

Used in armaments, aeronautics and sport (mechanical resistance) |

M.C.T. Can not be in any way responsible for the exploitation of the indicative data of this commercial document