Numerical simulation

In our businesses, the goal of numerical simulations is to validate the feasibility of a part, to increasethe quality of filling (for example to minimize the porosities), reduce the reject rate, optimise the production cost, to extend the tool life.

In recent years, the increase in computing power of computers and the simplification of software interfaces have allowed for greater democratization of their uses. The results are more easily exploitable to modify the design of parts and tools.

Two simulation methods exist: finite element calculation or by finished volumes .

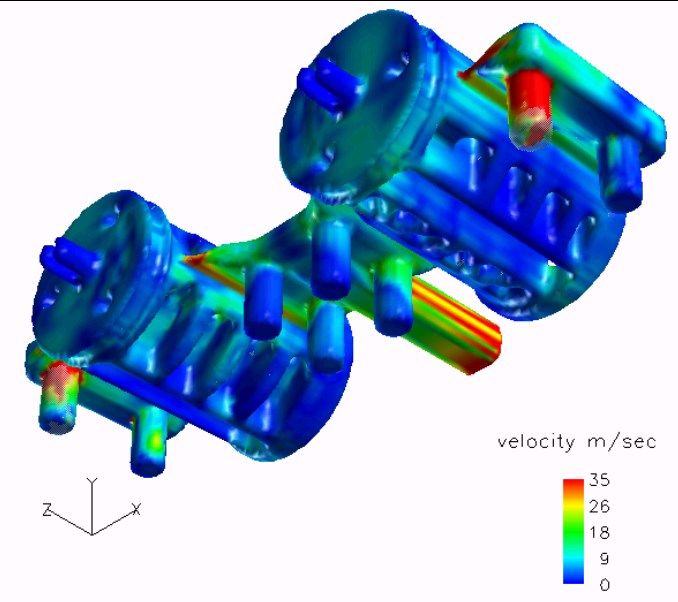

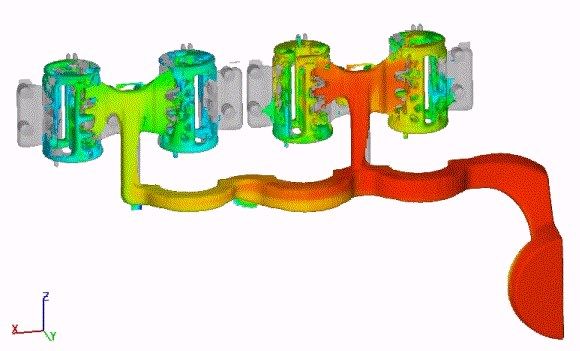

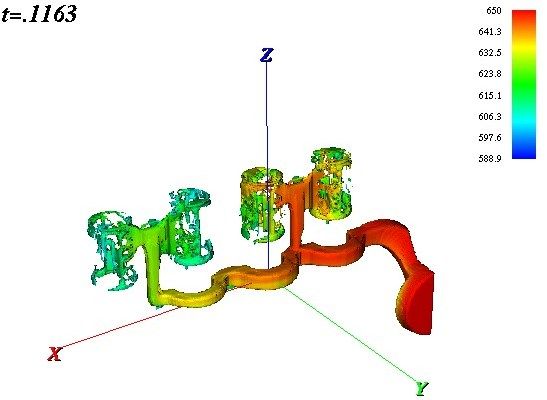

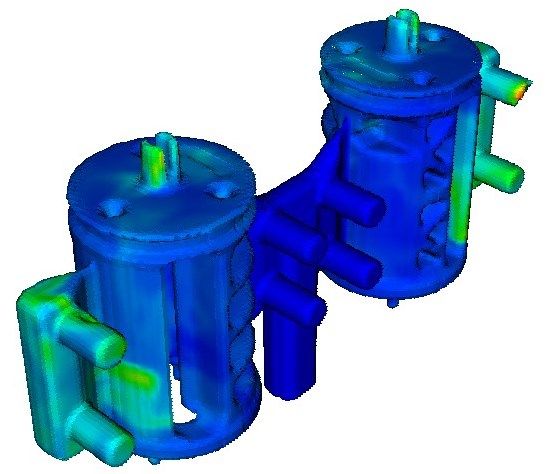

Theoretically finite element calculation is mathematically more precise because the structure of the mesh follows exactly the shape of the part whereas the other mode converts the form into a multitude of cubes. The choice of the size of the cubes makes the simulation more or less precise. The software calculates the required simulation parameters: pressure, temperature, filling, speed and other physical data of each cube, which in turn transmits them to neighboring cubes.

On the other hand, the processing time is smaller for simulations by finite volumes, which is an advantage when a study requires several successive simulations before finding the right solution.

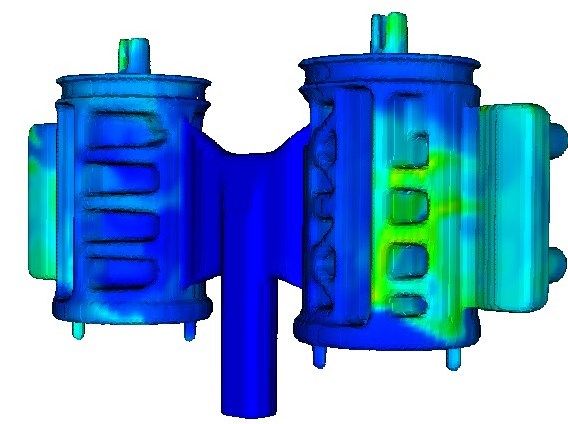

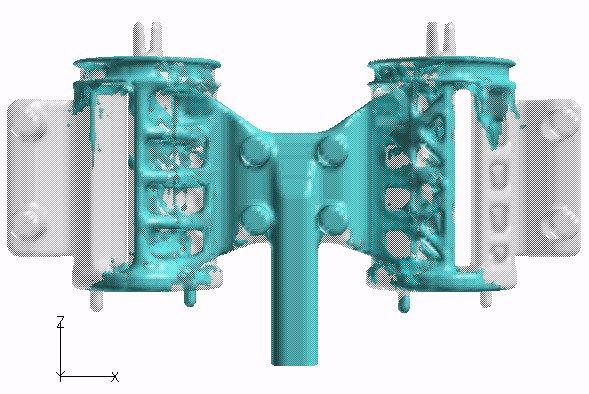

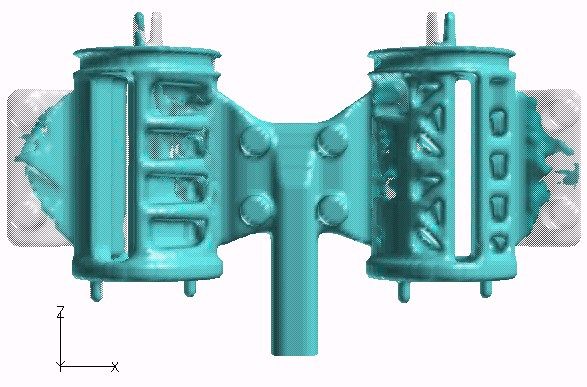

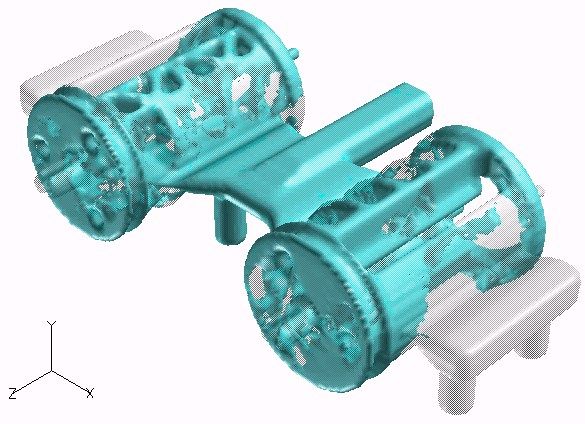

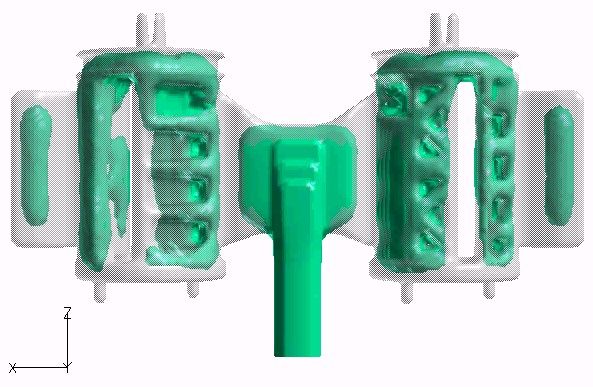

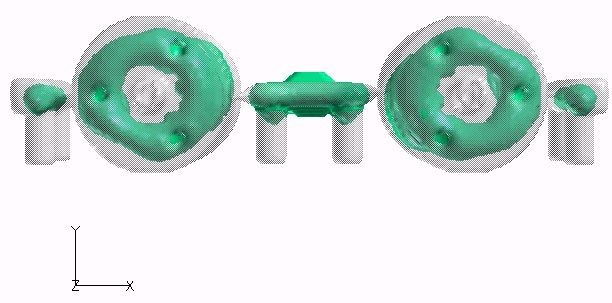

In high pressure die casting, simulations can be made in 3 step : the filling of the form (To check that the feeds are designed to naturally fill the shape of the mold), the solidification of the piece (to minimize the porosity and shrinkage in the critical zones and to check that the third phase can transmit the pressure to the metal at the end of filling), and the repetition of cycle of multiple times to validate the stability of the heat exchange with the mold in production (It is necessary to check that the cooling circuit of the mold is sufficient to work continuously and to reduce the cycle time).