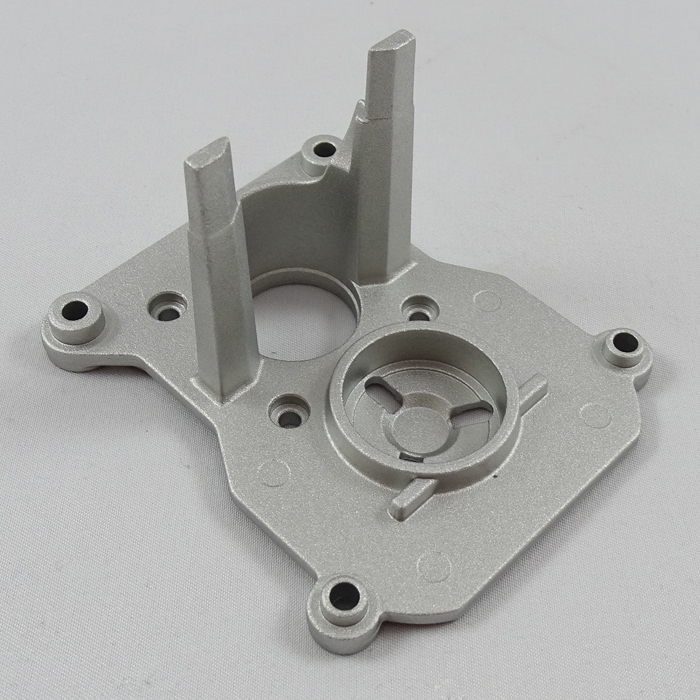

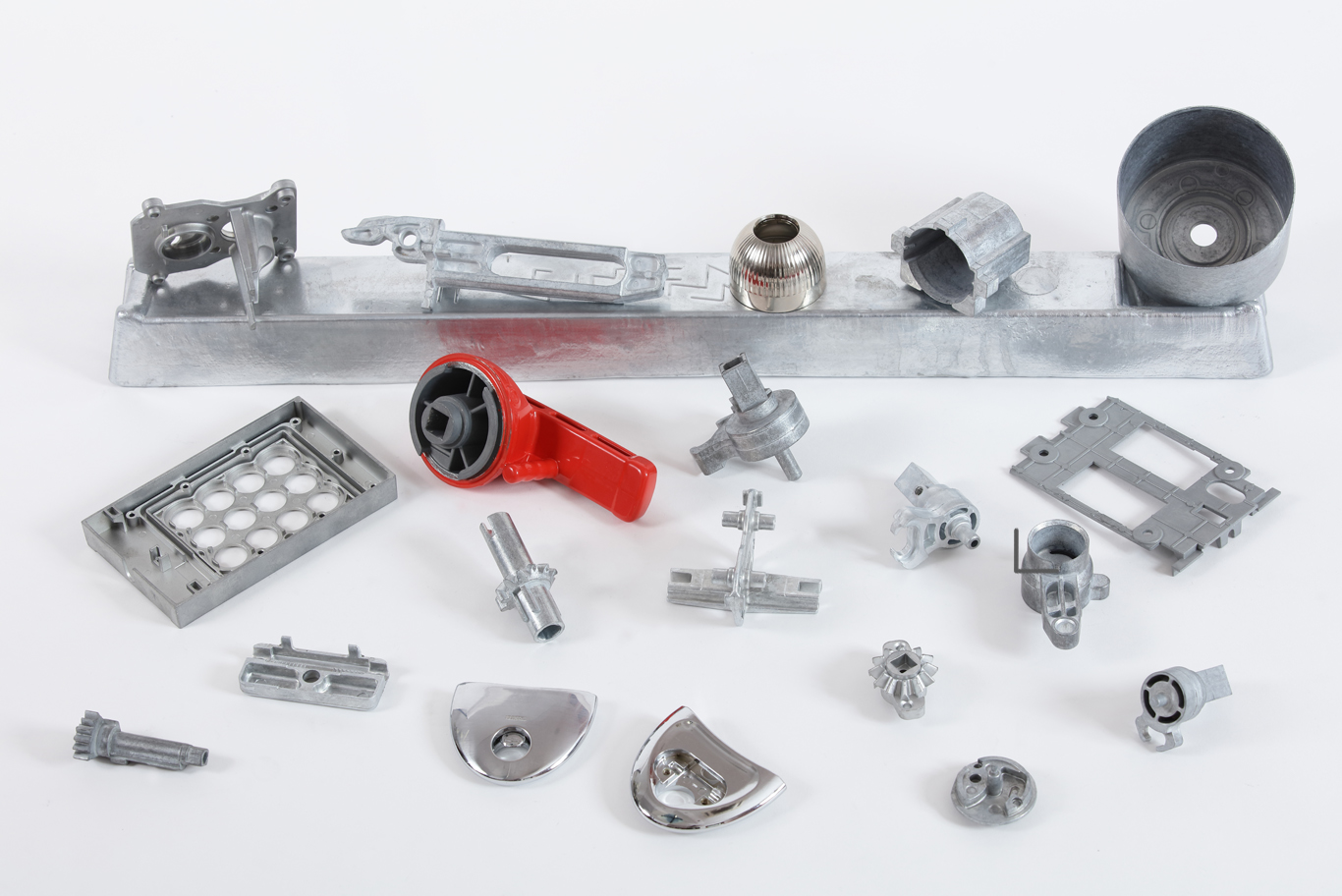

High pressure Zamak die casting

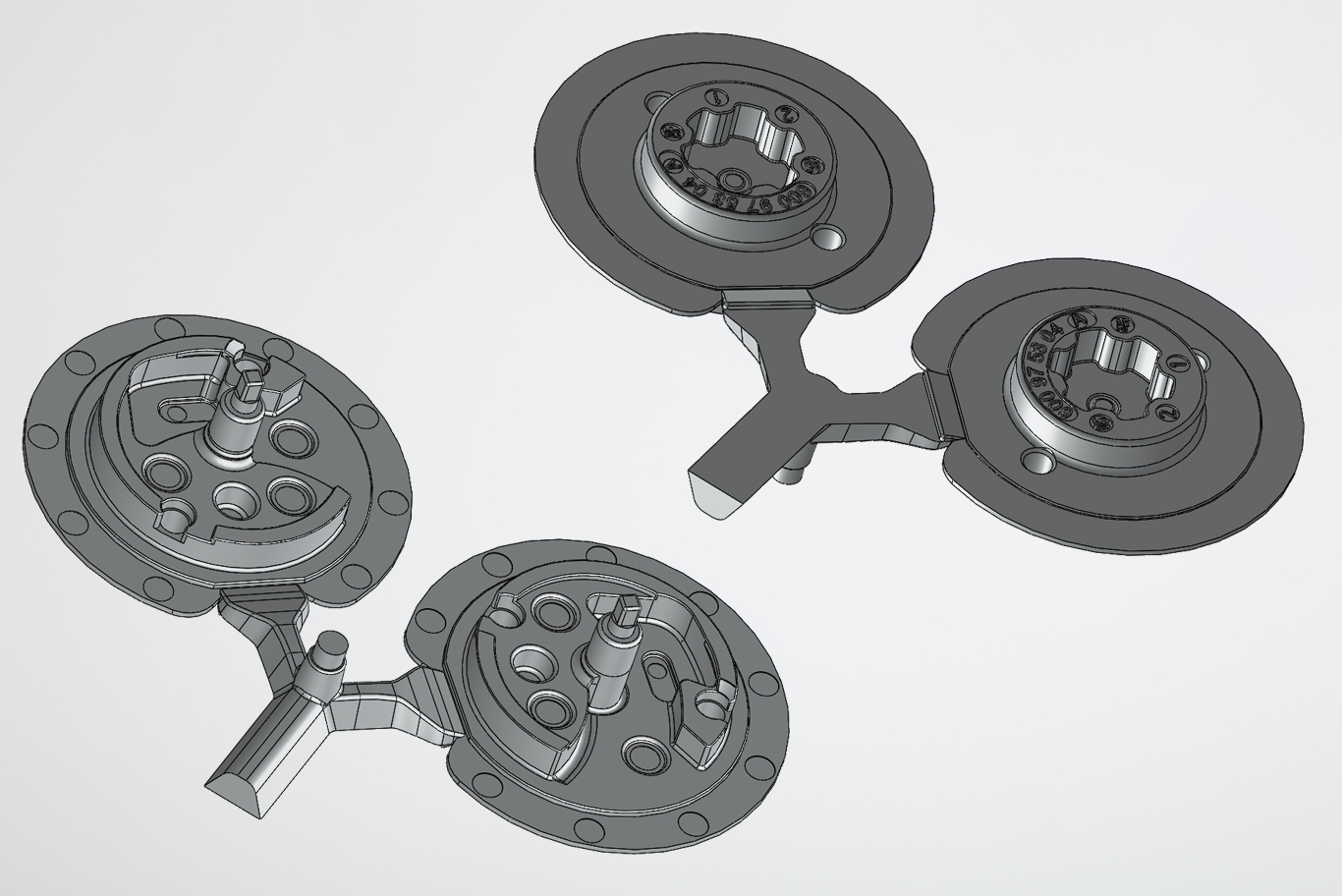

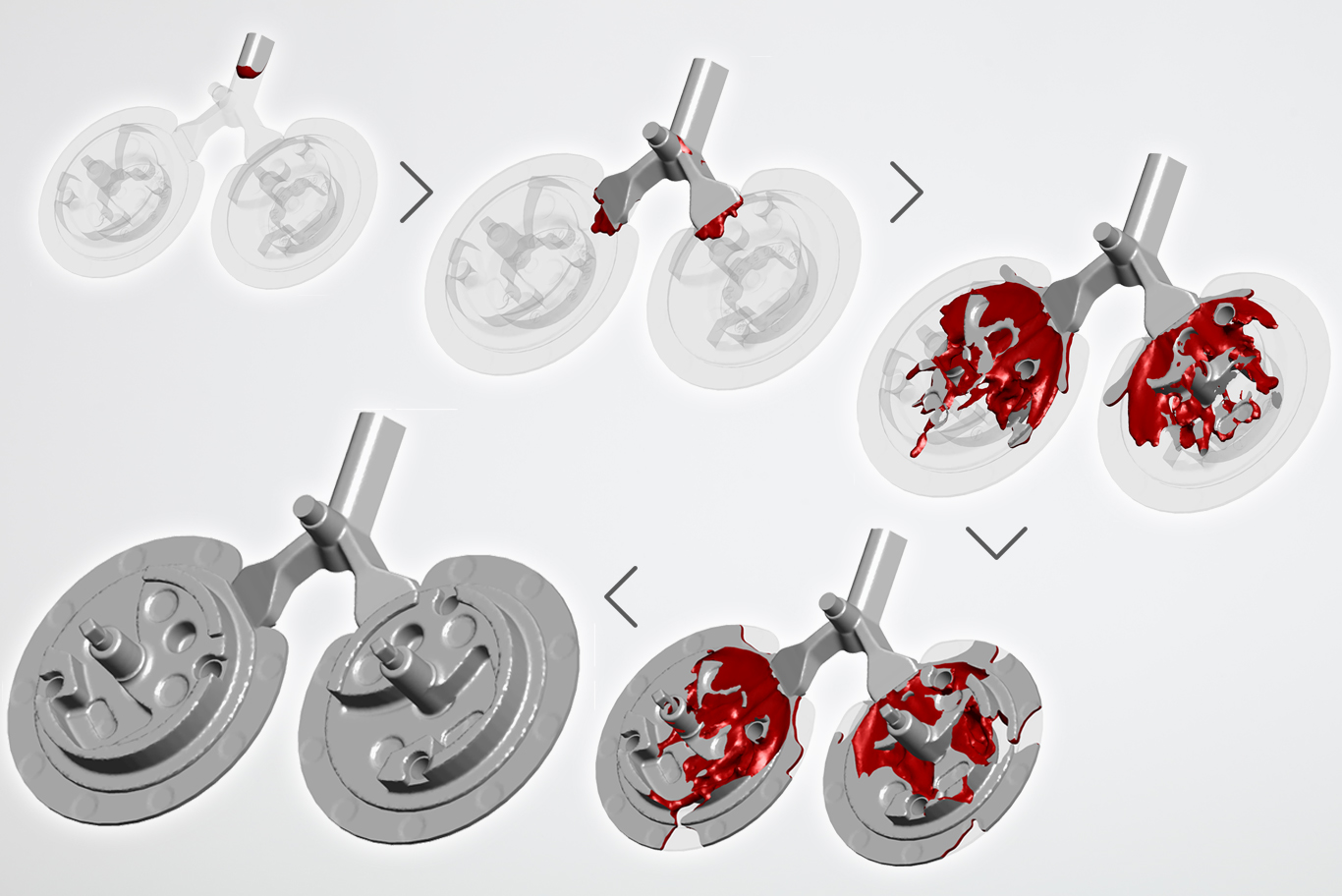

- The Zamak high pressure molding consist in injecting under high pressure a liquid alloy in a metalic mold that solidifies quickly to form a piece

- This process allows the production of thin pieces with complex form with very tight dimensional tolerances, limiting as much as possible the machining resumption

- One of his main advantages is to have a very high repeatability and a very high tool life

Characteristics of the zamak used in high pressure die casting

- The zamak has good mechanical characteristics, excellent flowability and very good dimensional stability

- It allows high production rates

- It also has good decoration and corrosion properties

- Recycling zamak is easy and economical, environmentally friendly

| European Standard EN1774 | Mechanical characteristics | Electric conductivity %IACS | Thermic conductivity W(m K) | ||||

| Densité | Rm N/mm² | Rp 0.2 N/mm2 | A% | HB | |||

| Zamak SAVE | 6.7 | ||||||

| ZL0400 (ZnAl4) Zamak 3 | 6.6 | 260/300 | 250/290 | 5/8 | 80/90 | 26 | 113 |

| ZL0410 (ZnAl4Cu1) Zamak 5 | 6.7 | 300/340 | 290/330 | 3/6 | 85/95 | 26 | 110 |

| ZL0430 (ZnAl4Cu3) Zamak 2 | 6.7 | 360/400 | 290/350 | 8 | 110/110 | 26 | 119 |

| Designation according to European Standard EN 1706

|

flowa-bility |

machin-ability |

welda-bility |

Polishing | chroming | plating | tinning | Painting | Silvering gilding |

Anod-isation |

Zink | corrosion resistance | Field of use |

| Zamak SAVE | A | B | B | A | B | B | C | B | B | F | A | E | Furniture, locksmithing, automobile |

|

ZL0400 (ZnAl4) Zamak 3 |

A | B | B | A | B | B | C | B | B | F | A | E | Furniture, locksmithing, automobile Improved shock and corrosion resistance |

| ZL0410 (ZnAl4Cu1) Zamak 5 | A | B | B | A | B | B | C | B | B | F | A | E | Furniture, locksmithing, automobile Improved tensile strength, improved shock resistance and dimensional stability |

| ZL0430 (ZnAl4Cu3) Zamak 2 | A | B | B | A | B | B | C | B | B | F | A | E | Furniture, locksmithing, automobile best comprimise hardness /Resistance Recommended in the case of mechanical parts (gearing) |

Aptitudes : A = Excellent, B = Good, C = Fair, D = Poor, E = Not recommended, F = Inappropriate

A zamak is considered stabilized after 8 weeks at room temperature. Zinc alloy parts may undergo certain bending, bending, cold-shaping operations, observing certain precautions. Elles peuvent aussi être assemblées par sertissage, bouterollage de collerettes et de parois minces, de rivets et de reliefs divers venus de fonderie. (?)

M.C.T. Can not be in any way responsible for the exploitation of the indicative data of this commercial document